Accessory Review: Tormek Sharpening System

By H. Clay Aalders

(Editor’s note: The following post originally appeared at The Truth About Knives. Used with permission of author)

Thanks to a very generous gift from my sponsor (in the form of a Woodcraft Xmas gift card from my wife), I took the plunge and bought a Tormek 2000 (older precursor to the T-7).

The Tormek is a low-speed, self watering, grinding wheel system. Imported from Sweden, it comes in two basic models, the consumer-grade T-3 and the larger, commercial grade T-7. Don’t let the grading fool you, the T-3 is not a delicate unit. Rather, the T-7 is probably just overkill for for those not sharpening mower blades, axes, or farm implements on a regular basis (it is warranted for 7 years of industrial use).

The T-3 comes with an 8” wheel (T-7 10”) that rotates vertically through a trough of water. Because the stone rotates slowly and is continuously lubricated and cooled, the tool’s edge does not lose its temper.

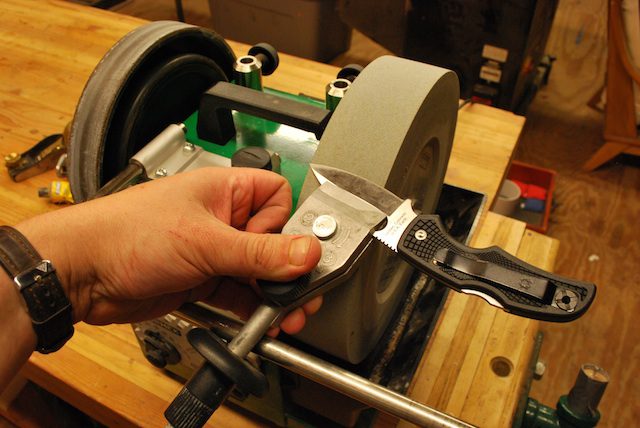

The heart of the Tormek system lies in the guide rod. This serves as a foundation for several dozen different jigs, most of which are sold separately. The rod can be positioned for grinding against or away from the rotation of the stone, and adjusts up/down to set the angle. Grinding angle is measured by the included gauge that even calibrates for changes in the stone’s diameter with use. The tool is clamped in the appropriate jig, and then you turn on the machine. Depending on the jig and the action required (they make jigs for any manner of lathe-turning gouges and knives, many of which resemble artifacts from the Spanish Inquisition), you slide the jig back and forth across the rod, with the cutting edge moving across the surface of the stone. Depending on the level of sharpening required, the wheel (normally 220 grit) can be prepped to 1000 grit by holding an included stone against the wheel.

Once the blade has been ground at proper angle, the final step is honing. On the other side of the Tormek, opposite the the grinding wheel, is the stropping leather. You impregnate the wheel with a small amount of light-tool oil (like you’d use with pneumatic tools), and then apply a bead of (included) pumice paste honing compound. You have the choice of using the jig and guide rod again, or simply free-handing it. Run the edge across the turning leather wheel for a few seconds (away from the direction of rotation!) and you’ll have a scalpel-like edge.

The biggest drawback of the Tormek system is the price. The base price of a T-3 unit is $379, and the T-7 is $639. The only included jig is the Right Angle one for chisels and handplane irons. There are two available knife jigs, the $38 standard model that’s suitable for most applications from a Swiss-Army knife all the way up to a medium-size chef’s knife. The Long Knife Jig ($54) helps stiffen longer blades such as those you would find on a filet knife, as well as providing more stability for larger knives.

The other drawback of the Tormek system is that while it excels at flatter grinds, you obviously can’t sharpen a serrated edge, and concave blades are difficult against a flat stone. Using the Tormek takes some practice; I would certainly recommend that you are comfortable sharpening more utility oriented blades before attacking one of your priceless collection pieces. For a typical edge, however, you can achieve results that are of professional quality – often better than a knife will come factory standard.

Included with the unit is a diamond dressing wheel. Used with the guide rod, this allows you to restore the grinding wheel to true and square, as use alters the flatness of the stone.

Conclusion

The Tormek is not for everyone, and its price certainly makes it an ‘investment.’ However, even the lower-price Tormek T-3 is built to last, and with a wide range of jigs it will provide you with a lifetime of optimally sharpened tools.