Editor’s Note: This piece originally appeared at The Truth About Knives as part of the “5 from the Grinder” series. Used with permission of the author (David C. Andersen). If you would like to be featured on KNIFEMagazine.com in a future 5ftG post, visit https://www.knifemagazine.com/5-from-the-grinder-form/ (password “grinder”).

At BLADE Show 2017 I (David C. Andersen) had the pleasure of being introduced to Pete Winkler of Cross Knives by a good friend. Pete is not only a Forged In Fire champion, he was also a heck of a nice guy to talk to for a few minutes amidst the flurry of activity that is BLADE. I loved his work. His square pins make quite a statement and his convex grinds were incredibly clean. Enough from me, onto Mr. Winkler himself!

My name is Pete Winkler, I am 64 yrs old and have been making knives for 7 years. The first year was mostly putting handles on blanks. I realized it was nice to do but I needed to make my own designs and learn to heat treat the knives I would build. I began doing that in early 2011. I initially marketed my knives at local Gunshows in Dayton and Cincinatti,Ohio. It has been my full-time work for the last 5.5 years and isn’t a job, I previously had been self- employed as a contractor.

Question 1: What knifemaker(s) or designer(s) have had the biggest influence on you? Do you have any mentors?

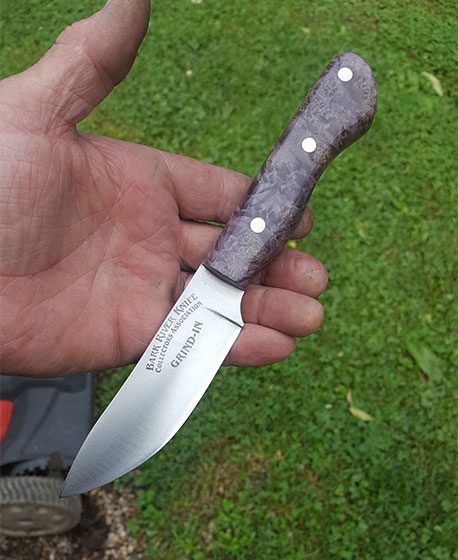

Through my life I have liked and used knives a lot. I used Buck and Browning folders back in the early 70’s and always had a Solingen steel hunting knife. I owned a couple of Western knives also. From those I got into the Marbles knives and then Bark River. I built my first start to finish full tang knife at a Bark River Grind-In Weekend. It was a great experience and sealed my fate to making knives.

I belong to the ABS and my blacksmith club, Southern Ohio Forge and Anvil have encouraged my forging and bladesmithing. Two friends, Mike Roberts and Steve Roth have shown me much and encouraged me to keep on. Both are ABS members and active in the club.

Question 2: What is your favorite knife pattern or style from history?

My favorite pattern or style would be a long slender bowie or Long knife. I have made a number of them. I don’t necessarily try to be historically perfect. Its a style that like and when I build one, I do my best on it, in my own style.

I like daggers too. The Arkansas toothpick with a 12-14 inch blade. Light and quick in the hand. A necessary belt accouterment back in the day.

Question 3: What is the next big thing in knifemaking? / What direction do you see the industry going?

I think the next big thing in making knives… will be a surge for more people to get into it. I am amazed at the ongoing contacts I have on almost a weekly basis from people wanting to get into making knives as a hobby. Knives are one of the oldest tools in the history of the world. People collect them, use them, trade them and that will never stop. Today, folders are hot, frame lock folders to liner locks to slip joints.

Big full tang knives are hot, hot. Custom everything is in demand. From art knives to swords and large weaponry. Damascus knives are just out of sight, with some of the damascus some makers are creating. Incredible talent and it is only going to go on and increase. Blade show was incredible a few weeks ago. It will be bigger next year.

Question 4: Is there a knife from your lineup that you feel best exhibits who you are as a knifemaker/designer in terms of design elements, aesthetic or techniques used?

The knife in my lineup that best exhibits who I am as a maker would be my All- Round Hunter.

It is a 5-5.5 inch blade .180 thick with a slight upsweep. It is what the name says. Its an All Round Hunter. Big enough for the largest big game on the continent, yet functional for smaller uses along with the ability to handle just about any BushCraft chores thrown at it. I began my knifemaking with a primary outlet of my knives going to outdoorsman. My ARH has proven itself in the field. Its a classic large hunter with good ergos and balance. It can be dressed up to be bit fancier or built using damascus.

I have built many, from simple Black Canvas micarta handles, to ones with bolsters, or guards. I have used CPM steels on them along with Damascus. As a custom maker I tell my customers, how ever you want it. I have one to build next month in Cpm3v steel and vine filework down the spine. It is getting some crazy blue dyed maple burl on the handles. It will get some use but be a show piece also.

Question 5: What is your EDC and why?

My EDC is my BushCrafter LT. Its a lighter knife with a full sized, but slimmer handle.. My personal one is the first prototype of this model that I made. It is made from 80Crv-2 steel, an excellent blade steel.

It also has burlap micarta for handles. my stepson Jackson started about a year ago making burlap and denim micarta and this was one of the first knives we put the burlap on.

I use this as an EDC because it is dexterous and I like to carry a belt knife when I can. Obviously I don’t wear one around the shop, But I have a small woods near me and a river runs thru it… and I love to get away there.

The BushCrafter LT cuts great feather sticks, I can whittle a spoon with it, clear a few small branches from my deer stand. Its my go-to. It cuts the mustard for me.

If you would like to see more of Pete’s work, you can check out the following.

Website (soon to be relaunched): www.buckeyecustomknives.com

Facebook: www.facebook.com/pete.winkler.9

Instagram: @crossknives